Industrial facilities stand as testaments to human ingenuity and progress. However, with their vast size, intricate machinery, and constant activity, they present unique challenges for construction and renovation projects. Their sheer size, complex equipment layout, and continuous occupancy demand advanced surveying techniques for accurate data capture without disrupting operations.

Traditional surveying methods struggle to keep pace with the needs of these environments, often resulting in inefficiencies and inaccuracies. This is where 3D laser scanning shines!

In this article, we’ll explore the importance of laser scanning for construction, renovations, and facility management in industrial settings, and address the specific challenges associated with scanning industrial buildings. Let’s dive in!

When To Use 3D Laser Scanning in Industrial Facilities?

Industrial plants are labyrinthine structures with hard-to-reach spaces, which make them nearly impossible to measure without accounting for potential risks and hazards. Moreover, many facilities run around the clock, so shutting down plants for measuring purposes can pose a major hurdle. But, with 3D laser scanning, owners can leverage the power of reality capture to overcome these challenges!

In addition, owners often want to build or redesign new facilities. However, in many instances, the current installation buildings lack plant layouts or past records.

The traditional method of documenting existing layouts usually involves tape measuring, which is prone to measurement mistakes like human error and changes that are not updated regularly. In these cases, a laser scanner can accurately supply the required data on current layouts for planning purposes. By documenting existing conditions, scanning serves as a verification tool, offering valuable insights for designers and engineers.

Advantages of 3D Laser Scanning

● Rapid Data Capture with High Accuracy and Detail

One of the most significant advantages of 3D laser scanning is its unparalleled accuracy and detail. 3D laser scanners can capture vast amounts of data in a fraction of the time compared to traditional methods.

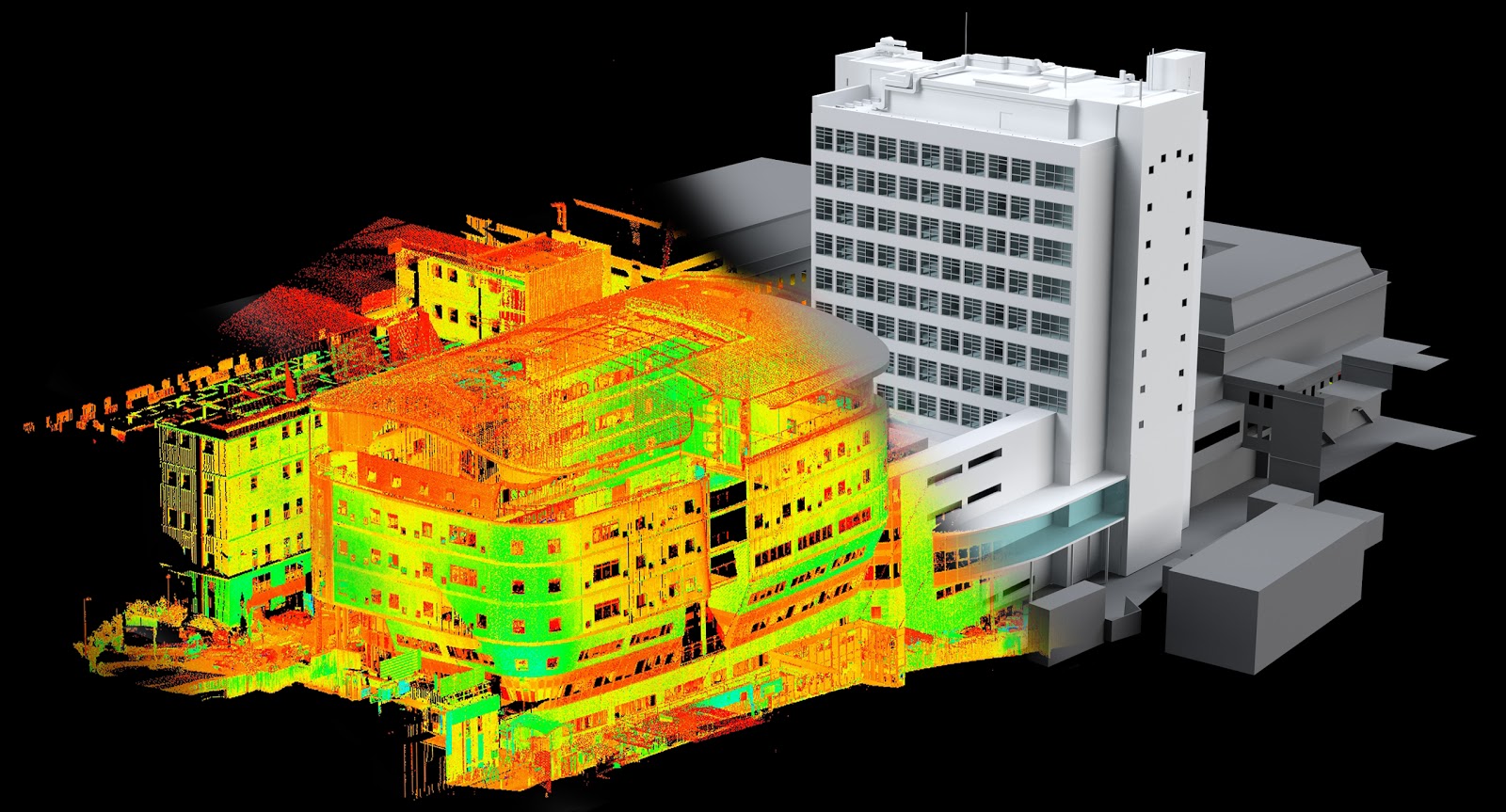

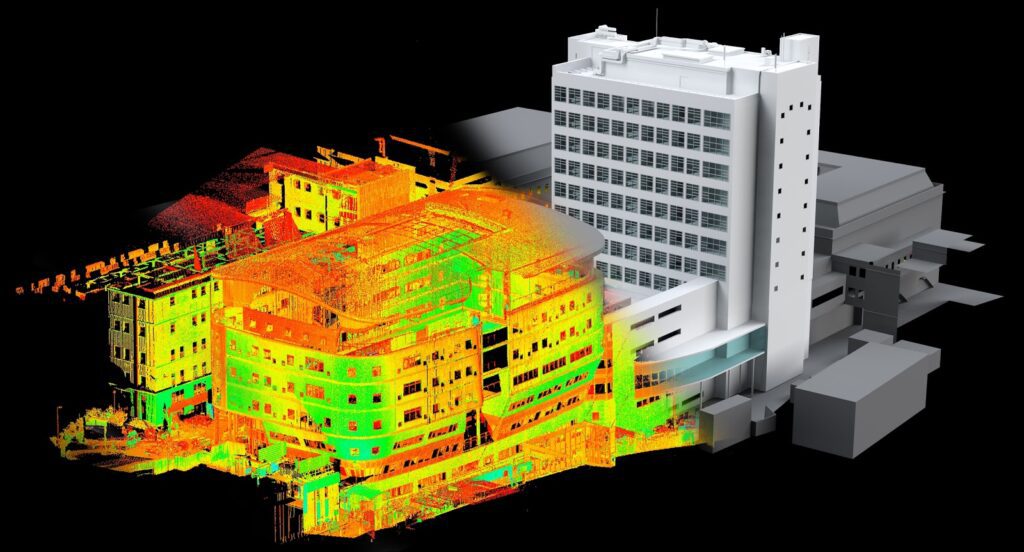

Advanced scanning devices emit thousands of laser pulses per second, generating highly detailed point clouds with sub-millimeter accuracy. These scanners can capture intricate features and nuances that may go unnoticed by traditional methods. This accuracy is invaluable in engineering and design processes, allowing AEC professionals to work with real-world data rather than relying solely on blueprints or outdated measurements.

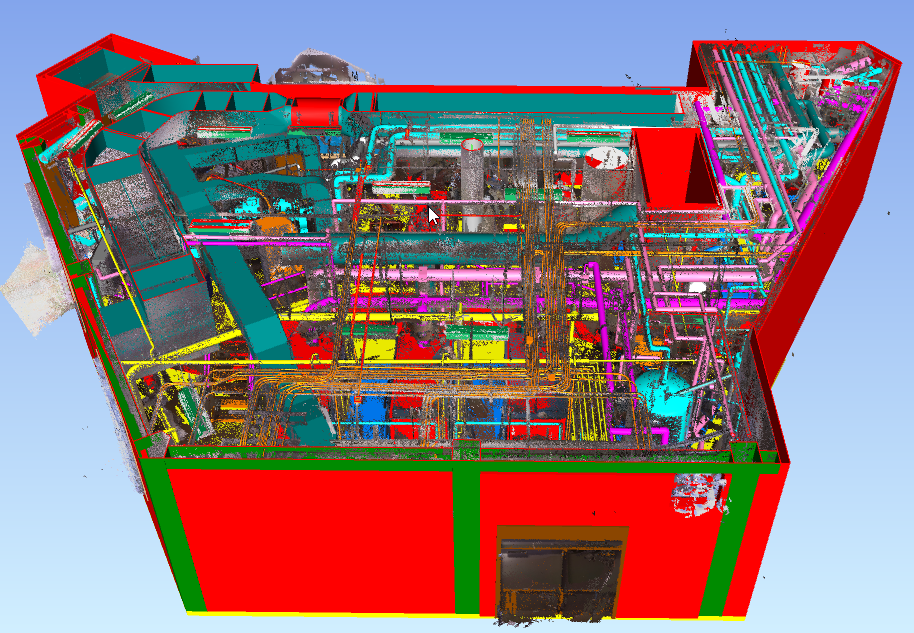

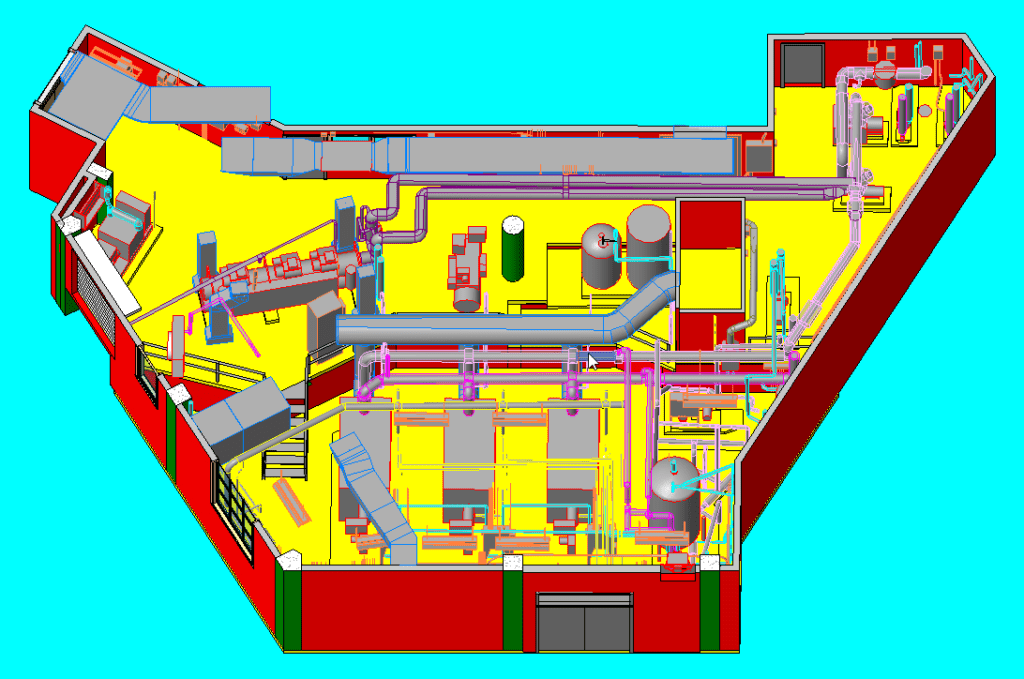

By capturing comprehensive data of machinery, equipment, pipelines, and infrastructure, scanning offers more accurate planning, retrofitting, and maintenance activities, while minimizing errors and optimizing resource utilization.

● Non-contact Precision for Comprehensive Coverage

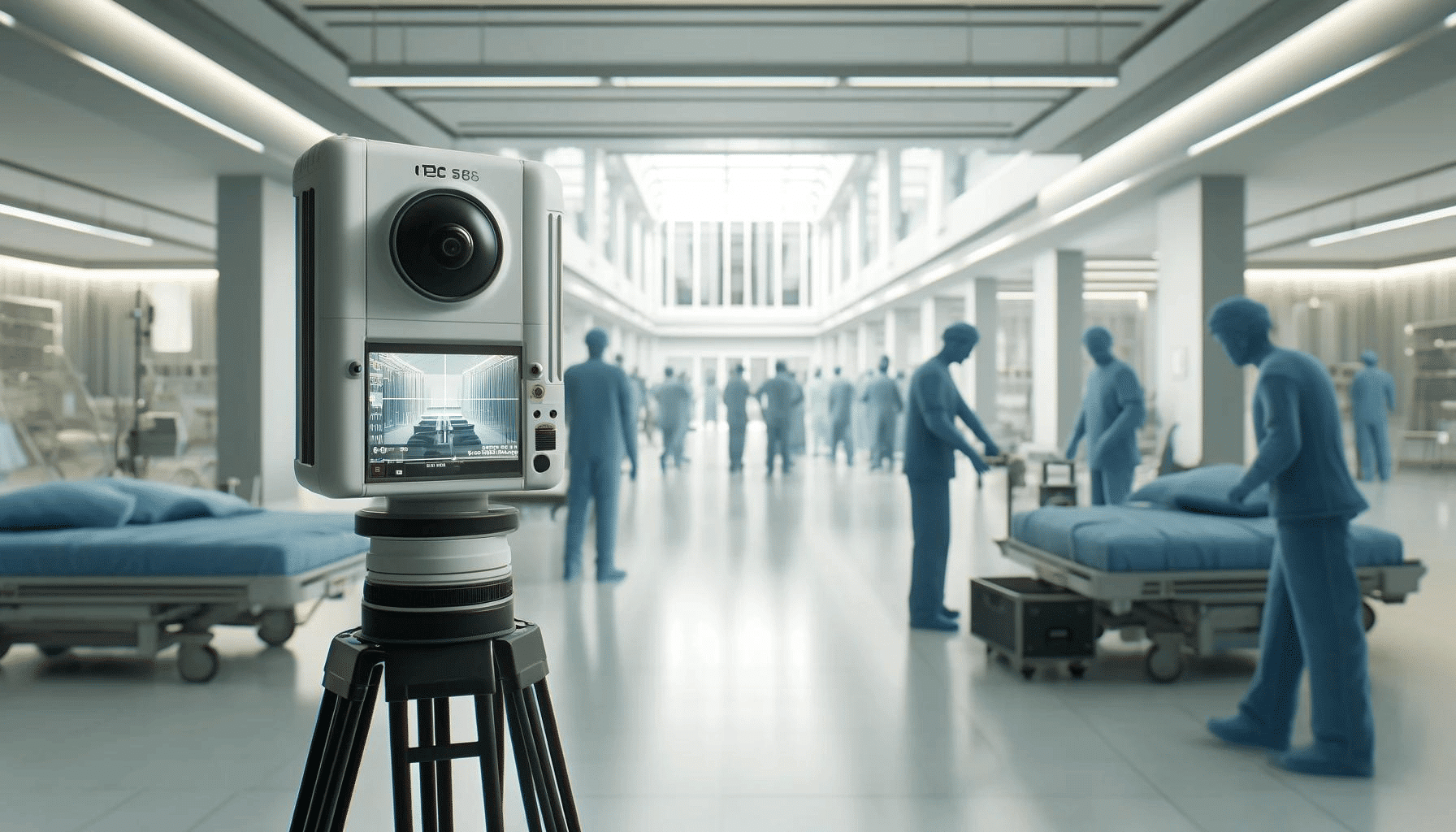

Unlike traditional methods, 3D laser scanning is entirely non-contact, eliminating the need for physical interaction with the surveyed objects. This not only ensures operator safety but also minimizes the risk of damage to delicate equipment or structures. With exceptional range and versatility, 3D scanning enables detailed coverage of industrial facilities, including hard-to-reach areas and complex geometries.

Laser scanners have the ability to capture 360-degree data from multiple vantage points, making sure no detail in sight is overlooked for facilitating thorough analysis and decision-making. Further, special tripods and accessories provide access to challenging areas above equipment or within interstitial spaces, ensuring comprehensive data collection without disrupting ongoing operations.

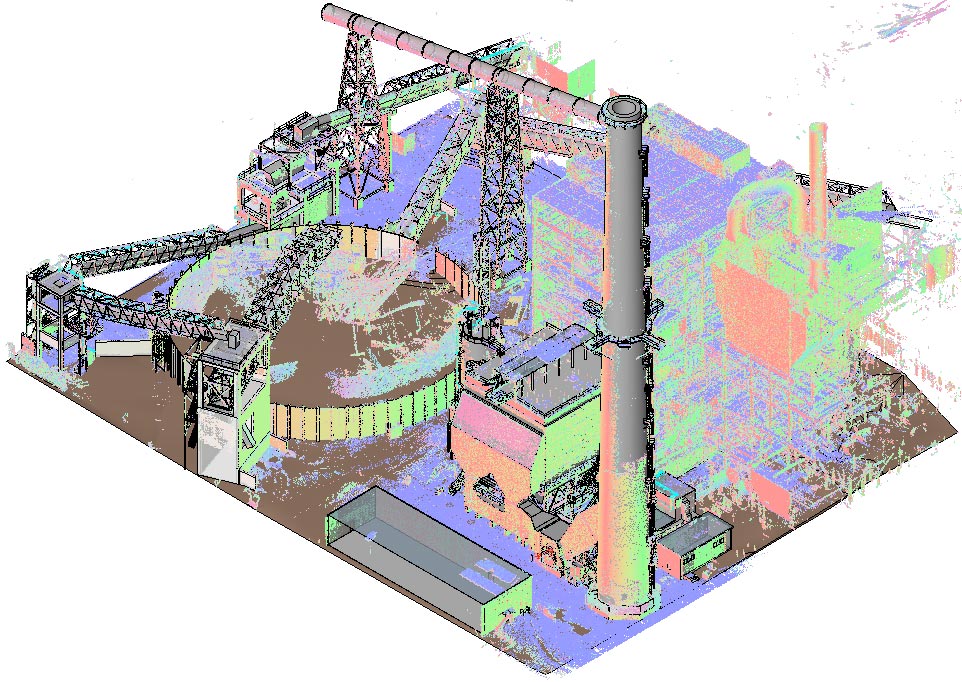

● Navigating the Complexity of Industrial Facilities

Industrial buildings are not just large but have complex configurations coupled with structural elements and machinery. Traditional surveying methods struggle to capture the intricacies of these environments, often leading to incomplete or inaccurate data. With its ability to swiftly and accurately capture these complexities, laser scanning emerges as the preferred choice for industrial renovations.

Additionally, mobile scanning devices are versatile tools that complement scanning efforts, by providing access to areas that are hard to reach. However, it’s crucial to strike a balance between accessibility and accuracy when choosing the right equipment for the task at hand.

● Time and Cost Savings

Traditional methods of surveying and documentation are labor-intensive and time-consuming. By reducing the need for manual measurement and surveying services, scanning lowers labor costs and accelerates project timelines. Moreover, the ability to detect design flaws and construction issues early in the project lifecycle minimizes costly rework and material wastage.

Additionally, achieving ongoing operations with minimal disruptions is considered one of the most significant challenges in industrial renovations. Through laser scanning and non-intrusive technologies, data is captured with minimal to no disruption to the normal pace of the facility. By avoiding downtime and interruptions, construction projects can proceed smoothly, ensuring timely completion and minimal impact on productivity.

Practical Applications of 3D Laser Scanning in Industrial Facilities

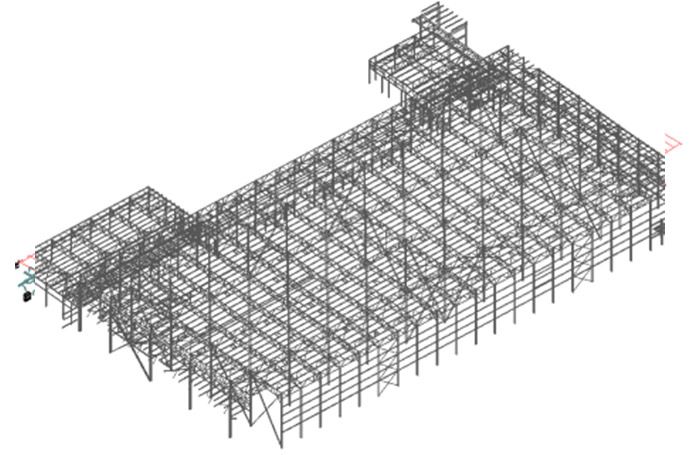

Design and Construction

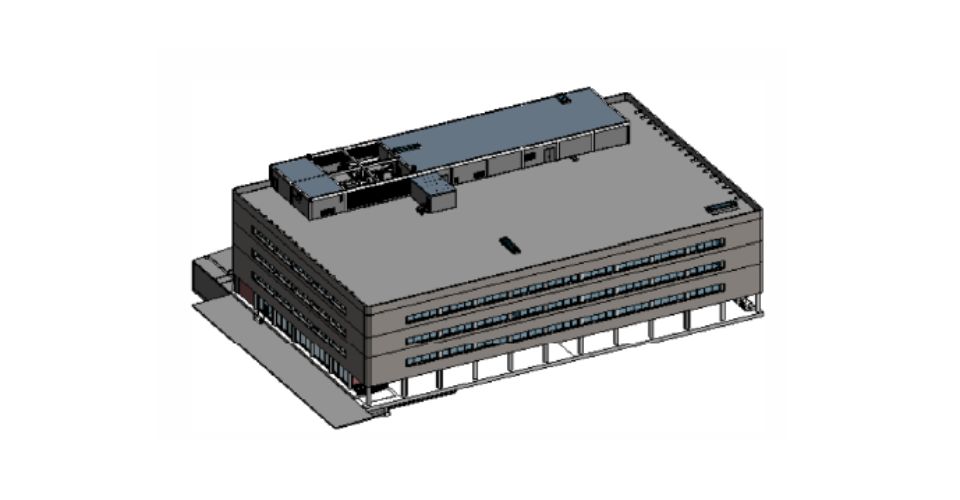

Effective collaboration is the cornerstone of successful industrial projects. 3D laser scanning streamlines the design and construction phases by enabling precise as-built documentation of existing structures and offering a source of truth for data sharing and visualization. Engineers, architects, and contractors can overlay new designs onto scanned models, ensuring compatibility and minimizing errors.

Additionally, the technology aids in identifying potential clashes and discrepancies early in the process, saving time and resources. Whether it’s conveying design concepts to clients or coordinating tasks among project teams, the ability to present detailed 3D models fosters clearer understanding and alignment.

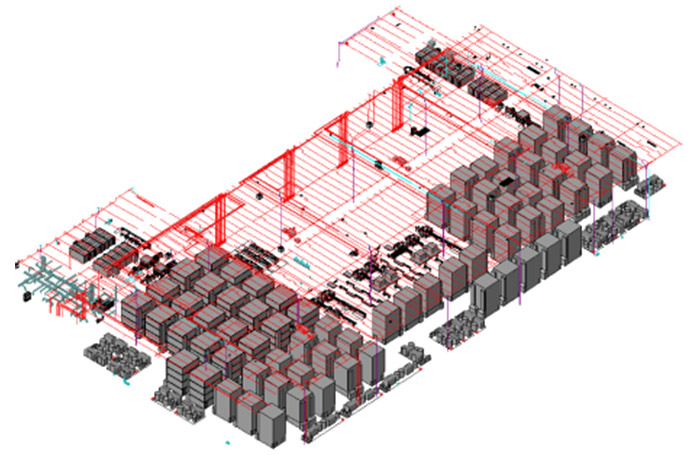

Facility management, Maintenance and Asset Management

Industrial facilities typically have a wide array of complex assets that require meticulous management to ensure operational efficiency and regulatory compliance. Equipment downtime of any kind can translate into significant financial losses. 3D laser scanning simplifies asset management and proactive maintenance by providing accurate data that enables the creation of digital twins of equipment and infrastructure. These digital replicas provide a comprehensive visual representation of assets, complete with detailed information about machinery, such as specifications, installation dates, and maintenance records.

By centralizing asset information in a digital format, facilities can streamline maintenance schedules, identify potential issues, minimize shutdown time, and extend the lifespan of critical equipment. Furthermore, the scanned models serve as invaluable references for spare parts procurement and retrofitting projects, contributing to significant cost savings and reinforcing the technology’s value.

Enhanced Safety and Compliance

Safety becomes non-negotiable in industrial environments, where workers are often exposed to hazardous conditions and high-risk activities. 3D laser scanning enhances safety by facilitating thorough risk assessments and hazard identification, as it eliminates the need for physical contact with surveyed objects and minimizes the risk of accidents or injuries. The non-destructive nature of laser scanning ensures the integrity of industrial assets, preserving their long-term reliability and performance.

By capturing detailed data points used for creating 3D models of the facility layout, including potential hazards such as confined spaces or obstructed pathways, stakeholders can proactively identify safety risks and implement appropriate mitigation measures. Additionally, scanned data can be utilized for virtual safety training, allowing workers to familiarize themselves with facility layouts and emergency procedures in a simulated environment, thereby significantly reducing potential risks.

Retrofitting and Renovation

As industrial facilities evolve, the need for retrofitting and renovation becomes inevitable. 3D laser scanning simplifies this process by enabling the generation of existing infrastructure from millions of captured data points. Engineers can assess structural integrity, evaluate space utilization, and plan modifications with precision. The technology minimizes disruptions to ongoing operations while maximizing the efficiency of renovation projects.

In Conclusion

While traditional scanning methods have served industrial facilities well in the past, the advent of 3D laser scanning technology heralds a new era of precision, efficiency, and innovation. This technology offers a transformative solution for industrial construction and renovation projects, surpassing traditional surveying methods in accuracy and adaptability. By leveraging advanced scanning technologies, construction professionals can navigate the design, construction, maintenance, and retrofitting of industrial structures with ease, ensuring seamless project execution and optimal outcomes.

The ability of 3D laser scanning to capture precise spatial data, streamline workflows, and enhance decision-making processes is pushing the boundaries of innovation and proving pivotal in revolutionizing construction techniques and renovation in industrial settings. By embracing 3D laser scanning technology, industries can position themselves for greater reliability, sustainability, and excellence.

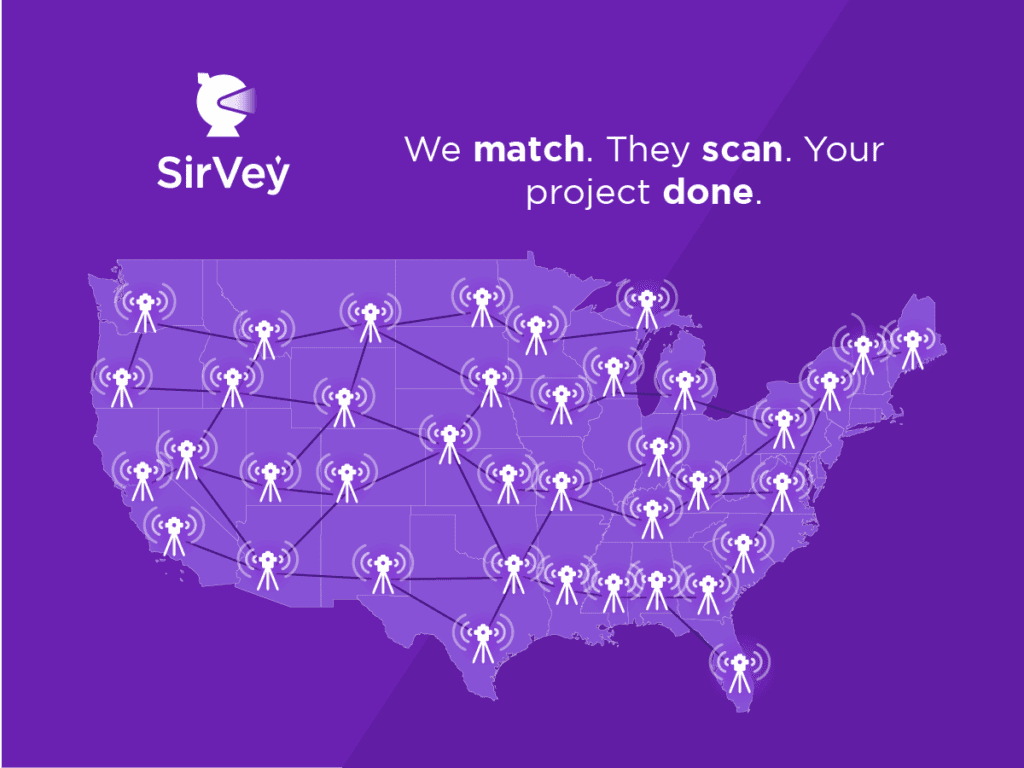

Interested in implementing 3D laser scanning technology for your next project?

Get in touch with us today to see how we can help!