Point Clouds and Laser scanning are crucial to understanding the existing site conditions and structures before starting a project in the AEC industry. Let’s dig more into them!

As the AEC industry becomes more competitive, delivering projects on time and within budget is more crucial than ever. However, measuring existing site conditions and structures using traditional methods often results in inaccuracies and inconsistencies, leading to project delays, rework, and cost overruns. Fortunately, laser scanning technology and point clouds are revolutionizing the way architects and engineers approach their projects.

Before we delve into the details of laser scanning technology, let’s first understand the basics and how you can benefit from this cutting-edge technology!

Laser Scanning

Also known as Reality Capture, High-Definition Surveying (HDS), or LiDAR (Light Detection and Ranging), Laser Scanning is a process of capturing and mapping detailed building data using laser beams. It is similar to taking a picture with your camera but with a much higher level of precision for each pixel. The resulting data is called a “point cloud,” which can be used to create 2D drawings such as plans, elevations, cross-sections, 3D textured models, and more. We will discuss point clouds in more detail shortly.

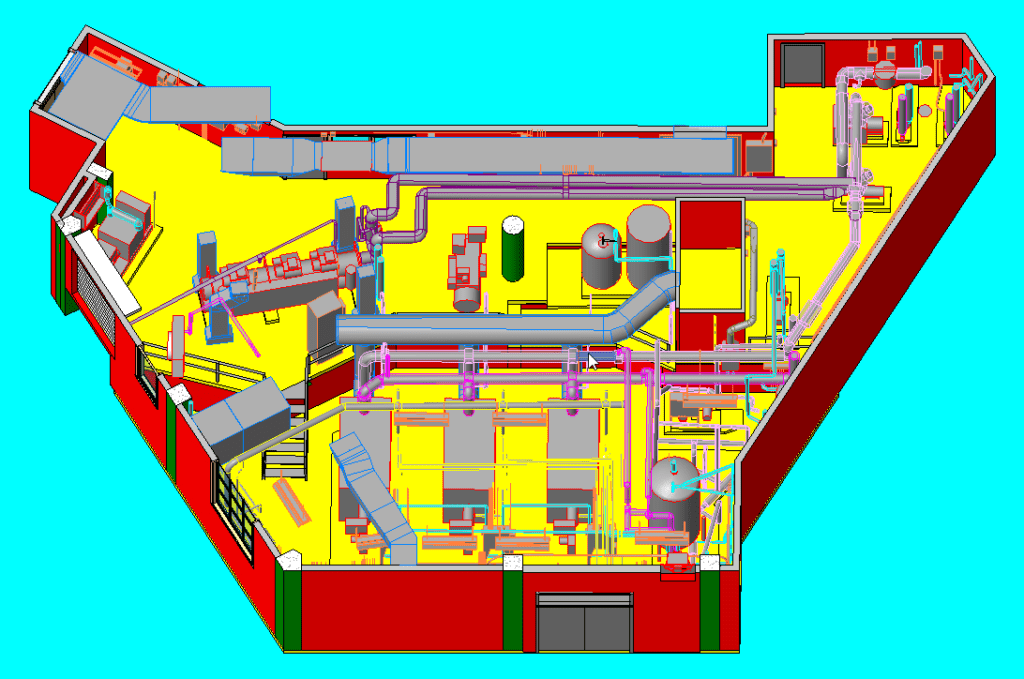

Although laser scanning technology has been available for decades, what has changed is the hardware and software that has enhanced its efficiency and reduced its cost, providing a more efficient way to get the job done. It can be used for designing purposes by adopting the scan-to-BIM application when the project starts, during construction for MEP coordination, and to create as-built records, retrofits, and renovations.

Learn more about Laser scanning and how it works.

Point Clouds

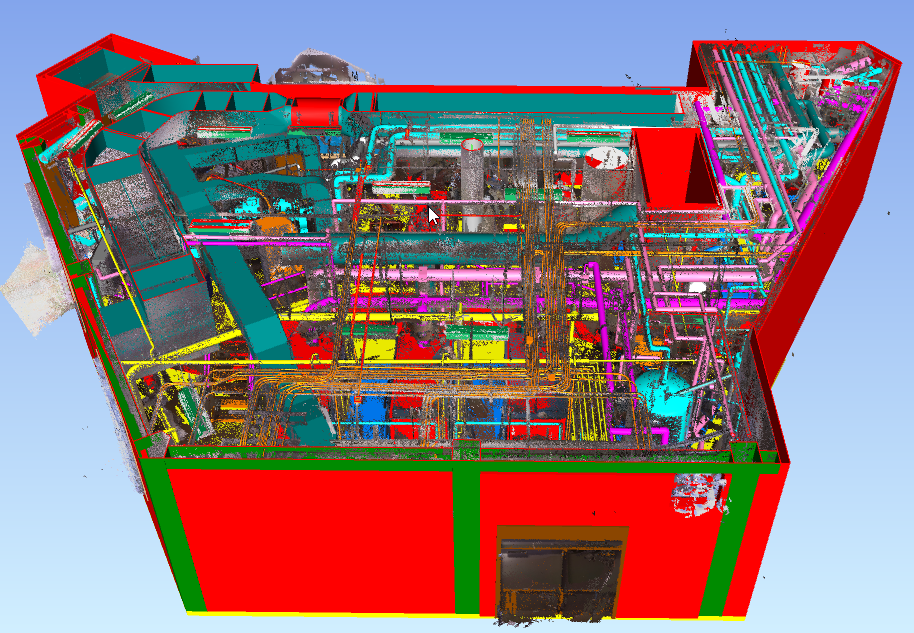

Point clouds are 3D point files that make up an object in digital space, each with X, Y, and Z coordinates. They contain vast information about an object, including its physical location, shape, color, and reflectivity. Through a process called registration, this dataset represents the spatial measurement as a whole.

Laser scanning generates a point cloud that comprises millions of data points, which can create a precise 3D model of any building. This point cloud can be easily imported into popular CAD or BIM software to generate 2D drawings or 3D renderings. Point clouds can be used to develop comprehensive floor plans, BIM models, track construction progress, and perform other functions.

Advantages of Point clouds and Laser Scanning Technology

Laser scanning produces a point cloud containing millions of data points that recreates an accurate 3D representation of any building. This technology offers significant benefits, such as:

Enhanced Speed and Accuracy

Architects and designers can enhance the accuracy and quality of their proposals, save time traveling between the office and job site, and devote more time to creating error-free design alternatives by utilizing laser scanning. This technology allows them to create detailed files for off-site review, resulting in reduced costs and time associated with revisits and rework.

Laser scanning also enables design professionals and contractors to obtain exact site dimensions with a simple scan. This facilitates the creation of well-coordinated drawings that seamlessly integrate structural elements, ductwork, electrical lines, and water pipes on the first attempt.

With laser scanning, millions of data points can be captured per second, providing precise geometric details of even the most intricate structures. This reduces the time required to measure field conditions and boosts overall productivity.

Streamlined Coordination

Laser scanning can aid in the creation of intelligent digital environments, promoting informed decision-making, outcome evaluation, and efficient productivity tracking. Integrative workflows can be developed, streamlining coordination and improving overall project performance.

The implementation of the scan-to-BIM technique allows design professionals to quickly identify errors and compare different project stages within the BIM environment. This also facilitates the use of modern manufacturing techniques, such as 3D printing and off-site material prefabrication.

In the current era of remote work, digital files provide easy access for all stakeholders, promoting real-time information sharing for collective decision-making, problem-solving, and enhanced coordination.

Insight into Existing Conditions

Scanned data provides valuable insight into existing site conditions that can be viewed in real-time, enabling on-the-spot decision-making if necessary. Accurate and comprehensive information reduces the likelihood of costly errors and rework.

Furthermore, scanning enables a thorough understanding of a site and the creation of accurate 3D models for large-scale projects in a short time frame. This approach helps identify and prevent errors, saving money and reducing manual labor.

Laser Scanning´s Challenges

Before finish, it´s important to notice that implementing laser scanning services has some challenges. First, it may have a higher upfront cost, but it helps lower the overall project cost when done right. Additionally, laser scanning relies on skilled and trained professionals to achieve the best results. Offering employee training to bridge the skill gap can add to the upfront costs. Finally, laser scanning can produce detailed drawings for any location, but to get the best outcome, it’s beneficial if the operator is familiar with the given site.

Conclusions

Point clouds and Laser scanning technology offer a new level of precision and accuracy that benefits AEC professionals. With its ability to capture and recreate 3D representations of existing buildings, this technology enhances speed and accuracy across all projects, streamlines coordination, and provides insight into existing conditions. Although there are challenges to implementing laser scanning services, the advantages far outweigh them, making this technology an essential tool for any AEC project.

At SirVey, we use the latest scanning hardware to provide as-built field measurements for any facility. We can process this data to deliver finished 2D drawing or 3D model files, tailored to meet our clients’ vision and goals. With our real-world expertise and years of experience, we deliver best-in-class results.

If you are interested in implementing point clouds and laser scanning services for your next project, reach out to us at SirVey today to discover how we can assist you!